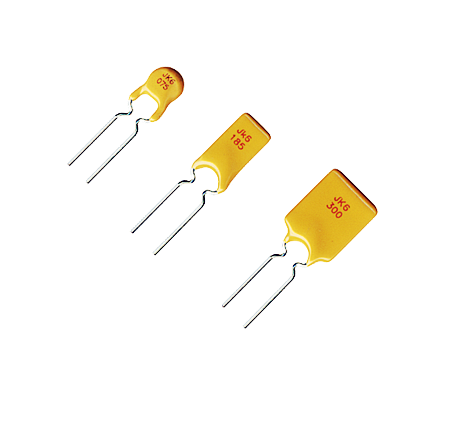

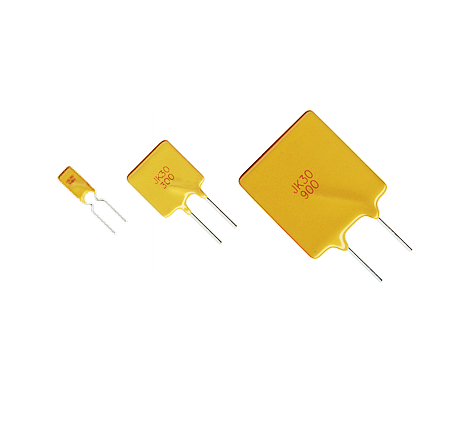

PPTC Resettable Fuse

Ultra-low Resistance PPTC

One-Time Fuse

TVS Diodes

Automotive TVS

Thyristor Surge Suppressors

GDT/Gas Discharge Tubes

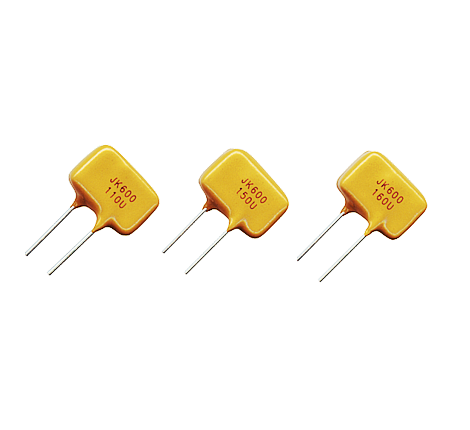

MOV/Varistor

SPG/Spark Gap Tube

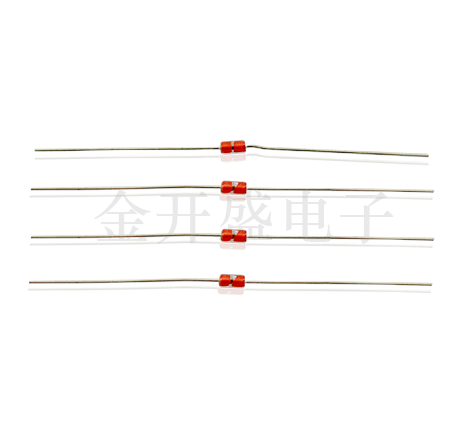

What is MOV varistor?

2018-03-14A varistor is an electronic component with an electrical resistance that varies with the applied voltage.[2] Also known as a voltage-dependent resistor (VDR), it has a nonlinear, non-ohmic current–voltage characteristic that is similar to that of a diode. In contrast to a diode however, it has the same characteristic for both directions of traversing current. At low voltage it has a high electrical resistance which decreases as the voltage is raised.

Varistors are used as control or compensation elements in circuits either to provide optimal operating conditions or to protect against excessive transient voltages. When used as protection devices, they shunt the current created by the excessive voltage away from sensitive components when triggered.

The name varistor is a portmanteau of varying resistor. The term is only used for non-ohmic varying resistors. Variable resistors, such as the potentiometer and the rheostat, have ohmic characteristics.

A varistor remains non-conductive as a shunt-mode device during normal operation when the voltage across it remains well below its "clamping voltage", thus varistors are typically used for suppressing line voltage surges. Varistors can fail for either of two reasons.

A catastrophic failure occurs from not successfully limiting a very large surge from an event like a lightning strike, where the energy involved is many orders of magnitude greater than the varistor can handle. Follow-through current resulting from a strike may melt, burn, or even vaporize the varistor. This thermal runaway is due to a lack of conformity in individual grain-boundary junctions, which leads to the failure of dominant current paths under thermal stress when the energy in a transient pulse (normally measured in joules) is too high (i.e. significantly exceeds the manufacture's "Absolute Maximum Ratings"). The probability of catastrophic failure can be reduced by increasing the rating, or using specially selected MOVs in parallel.[6]

Cumulative degradation occurs as more surges happen. For historical reasons, many MOVs have been incorrectly specified allowing frequent swells to also degrade capacity.[7] In this condition the varistor is not visibly damaged and outwardly appears functional (no catastrophic failure), but it no longer offers protection.[8] Eventually, it proceeds into a shorted circuit condition as the energy discharges create a conductive channel through the oxides.

The main parameter affecting varistor life expectancy is its energy (Joule) rating. Increasing the energy rating raises the number of (defined maximum size) transient pulses that it can accommodate exponentially as well as the cumulative sum of energy from clamping lesser pulses. As these pulses occur, the "clamping voltage" it provides during each event decreases, and a varistor is typically deemed to be functionally degraded when its "clamping voltage" has changed by 10%. Manufacturer's life-expectancy charts relate current, severity and number of transients to make failure predictions based on the total energy dissipated over the life of the part.

In consumer electronics, particularly surge protectors, the MOV varistor size employed is small enough that eventually failure is expected.[9] Other applications, such as power transmission, use VDRs of different construction in multiple configurations engineered for long life span. [10]

Previous:nothing!

Next:nothing!

PRODUCTS

CONTACT US

Shenzhen JKSEMI Electronics Co., Ltd.

Tel:+86-0755-26626670

Sales Skype: katemini86

Sales QQ:3502201273

E-mail: kate@jksemi.com(Sales)

Web:www.jksemi.com

Follow Us

Copyright@ 2013-2018 深圳市金开盛电子有限公司 All Rights Reserved. 粤ICP备18041324号-1